US Manufacturing Renaissance: Trillion-Dollar Tech Upgrades Boost

The US manufacturing renaissance, propelled by the $1 trillion infrastructure bill, is catalyzing unprecedented technological advancements, reshifting global supply chains and economic paradigms by fostering innovation and domestic production.

The notion of a US Manufacturing Renaissance: Leveraging the $1 Trillion Infrastructure Bill for Tech Upgrades might seem ambitious, yet a closer look reveals a potent confluence of policy, investment, and technological advancement poised to redefine the American industrial landscape. This isn’t merely about bringing jobs back; it’s about fundamentally transforming how goods are produced, emphasizing efficiency, sustainability, and competitive edge in a new global economy. The Infrastructure Investment and Jobs Act (IIJA) serves as a formidable catalyst, injecting crucial capital into critical sectors.

The Infrastructure Bill’s Foundational Impact on Modern Manufacturing

The Infrastructure Investment and Jobs Act, often referred to as the Bipartisan Infrastructure Law, marks a pivotal moment for American industry. While its primary focus might appear to be roads, bridges, and public transit, its broader implications for manufacturing are profound, providing the essential bedrock upon which modern, technologically advanced factories can thrive. This legislative package understands that robust physical infrastructure is not just about connectivity, but about enabling the efficient movement of goods, data, and energy – all critical components for a manufacturing renaissance.

At its core, the bill allocates substantial funding designed to upgrade and build out America’s aging infrastructure. This includes significant investments in broadband internet, which is indispensable for implementing Industry 4.0 technologies such as the Internet of Things (IoT) and artificial intelligence (AI) in factory settings. Furthermore, improvements to ports, railways, and highways directly reduce logistics costs and increase the speed of supply chains, making domestic production more competitive against international alternatives. A manufacturing sector cannot flourish without the efficient arteries to transport raw materials and finished products.

Enhanced Connectivity and Grid Modernization

One of the most transformative aspects of the IIJA for manufacturing is its commitment to nationwide broadband expansion and grid modernization. Reliable, high-speed internet is no longer a luxury but a necessity for modern factories that increasingly rely on data-driven operations, predictive maintenance, and artificial intelligence. The bill addresses this by:

- Bridging the Digital Divide: Funding for broadband deployment ensures even rural manufacturing hubs can access the connectivity needed for advanced digital integration.

- Smart Grid Development: Investments in a resilient, smart electrical grid are essential for powering energy-intensive manufacturing processes and supporting the adoption of renewable energy sources, leading to more sustainable and cost-effective operations.

- Cybersecurity Enhancements: Protecting critical infrastructure from cyber threats extends to the operational technology (OT) systems within manufacturing facilities, safeguarding intellectual property and production lines.

These infrastructure upgrades are not simply about convenience; they are about laying the groundwork for a manufacturing sector that is more agile, resilient, and technologically sophisticated. By addressing these fundamental needs, the infrastructure bill acts as a growth accelerator, making the US an increasingly attractive location for advanced manufacturing investments.

Technological Upgrades: The Core of the Renaissance

The manufacturing renaissance underway in the US is not simply a quantitative increase in production; it is fundamentally a qualitative transformation driven by technological upgrades. The availability of significant capital, partly spurred by the $1 trillion infrastructure bill and related domestic investment incentives, is allowing companies to adopt cutting-edge technologies that redefine factory floors and supply chains. This shift is critical for boosting productivity, improving quality, reducing costs, and enhancing global competitiveness.

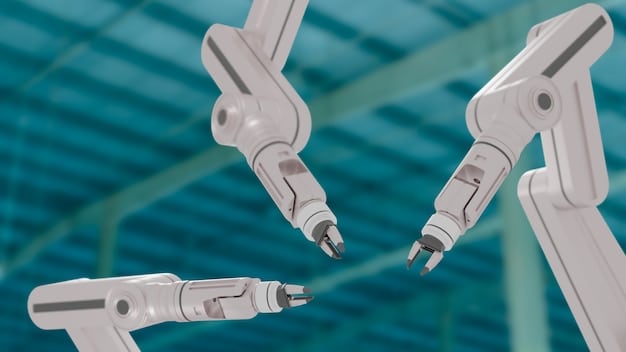

At the forefront of this technological wave are advancements in automation and robotics. Modern robotic systems are far more versatile and intelligent than their predecessors, capable of complex tasks, precision assembly, and even collaborative work with human employees. This isn’t about replacing human labor wholesale, but rather augmenting it, allowing workers to focus on higher-value tasks, quality control, and innovation, while robots handle repetitive, strenuous, or hazardous operations. The goal is to create a symbiotic relationship between human ingenuity and machine efficiency.

Embracing Industry 4.0: AI, IoT, and Data Analytics

The true power of this technological evolution lies in the widespread adoption of Industry 4.0 paradigms. This involves the integration of artificial intelligence (AI), the Internet of Things (IoT), and advanced data analytics into every facet of the manufacturing process. These technologies create “smart factories” where machines communicate with each other, production lines self-optimize, and predictive insights prevent costly breakdowns.

- Artificial Intelligence (AI): AI algorithms are being deployed for predictive maintenance, quality inspection, inventory management, and even generative design, optimizing product development cycles.

- Internet of Things (IoT): Sensors embedded in machinery, products, and supply chain components collect vast amounts of real-time data, providing unprecedented visibility and control over operations.

- Data Analytics: Large datasets generated by IoT devices are analyzed to identify inefficiencies, optimize energy consumption, improve product design, and forecast demand with greater accuracy.

Beyond these, advanced materials such as composites, nanomaterials, and additive manufacturing (3D printing) are reshaping product design and production possibilities. These innovations allow for the creation of lighter, stronger, and more complex components with reduced material waste and shorter lead times. The confluence of these technologies creates a manufacturing ecosystem that is more responsive, resilient, and capable of producing highly customized goods at mass production scales.

Reshoring and Supply Chain Resilience

The global events of recent years, particularly the COVID-19 pandemic and geopolitical tensions, underscored the fragility of extended global supply chains and highlighted the risks associated with over-reliance on single geographic regions for critical components. This realization has significantly accelerated the trend of reshoring – bringing manufacturing operations back to the United States – and nearshoring, relocating them to nearby countries. The $1 trillion infrastructure bill, alongside other policy initiatives like the CHIPS and Science Act, plays a crucial role in making the US a more attractive destination for these activities.

Reshoring isn’t simply a nostalgic aspiration; it’s a strategic imperative driven by a desire for greater supply chain resilience, reduced lead times, improved quality control, and enhanced national security, especially for sensitive industries. By localizing production, companies can better mitigate disruptions caused by geopolitical shifts, natural disasters, or pandemics. The ability to monitor and control the entire production process within national borders provides a level of certainty and agility that offshore models often lack.

Mitigating Global Disruptions

The primary driver for reshoring is the need to build more robust and less vulnerable supply chains. Diversifying manufacturing locations and bringing critical production closer to home offers several advantages:

- Reduced Lead Times: Shorter distances mean faster delivery of components and finished goods, improving responsiveness to market demand.

- Enhanced Quality Control: Proximity allows for more direct oversight of manufacturing processes, leading to higher product quality and fewer defects.

- Intellectual Property Protection: Producing domestically reduces the risk of intellectual property theft and unauthorized dissemination of proprietary designs and technologies.

Furthermore, the availability of skilled labor, albeit a challenge, is being addressed through various workforce development programs. The infrastructure bill’s emphasis on modernizing port infrastructure and transportation networks directly supports reshoring efforts by ensuring that raw materials can be efficiently moved within the US and finished goods can be distributed to domestic and international markets. This comprehensive approach, combining legislative support, technological adoption, and a strategic focus on resilience, effectively nurtures the reshoring trend.

Workforce Development for the New Era of Manufacturing

The emergence of a technologically advanced manufacturing sector, fueled by the infrastructure bill’s investments, necessitates a similarly advanced workforce. The skills gap in manufacturing is a well-documented challenge, with many current roles requiring a blend of technical expertise, digital literacy, and problem-solving abilities that traditional education pathways may not fully address. The manufacturing renaissance is not about fewer jobs, but different jobs – roles that interact with robotics, manage data analytics platforms, program AI systems, and maintain complex automated machinery.

Addressing this challenge requires a concerted effort from government, industry, and educational institutions to develop robust workforce development programs. These initiatives must focus on both upskilling the existing labor force and attracting new talent to manufacturing careers. This involves creating apprenticeship programs, vocational training opportunities, and partnerships between community colleges and manufacturing companies to tailor curricula to immediate industry needs. The goal is to build a talent pipeline that can sustain the growth of an increasingly sophisticated production ecosystem.

Bridging the Skills Gap with Education and Training

Investing in the human capital of the manufacturing sector is as crucial as investing in physical infrastructure and technology. Key strategies include:

- Apprenticeships and On-the-Job Training: Providing hands-on experience and direct mentorship allows workers to learn new skills in real-world manufacturing environments.

- Community College Partnerships: Collaborations between local manufacturers and community colleges can ensure training programs are directly aligned with industry demand for specific technical skills.

- STEM Education: Promoting science, technology, engineering, and mathematics (STEM) from an early age helps build a foundational knowledge base for future manufacturing professionals.

Moreover, the perception of manufacturing careers needs to evolve. Modern manufacturing facilities are clean, high-tech environments that offer competitive wages and opportunities for career advancement. By showcasing these aspects, and emphasizing the exciting challenges of working with cutting-edge technology, the industry can attract a diverse pool of talent, ensuring a sustainable and skilled workforce for the future of American manufacturing.

Financial Incentives and Policy Support Beyond IIJA

While the $1 trillion Infrastructure Investment and Jobs Act (IIJA) is a monumental piece of legislation, it is important to recognize that the US manufacturing renaissance is also being driven by a broader array of financial incentives and strategic policy support. These complementary measures reinforce the objectives of the IIJA, creating a more comprehensive ecosystem designed to stimulate domestic production, foster innovation, and enhance competitiveness. This multi-pronged approach demonstrates a concerted effort at the federal and state levels to nurture a thriving manufacturing sector.

The CHIPS and Science Act, for example, represents a significant investment in bolstering domestic semiconductor manufacturing, a critical component across virtually all modern technologies. This act provides substantial funding for semiconductor research, development, and production, aiming to reduce reliance on foreign supply chains for these essential microchips. Similarly, the Inflation Reduction Act (IRA) includes significant tax credits and incentives for clean energy manufacturing, electric vehicle production, and other green technologies, aligning manufacturing growth with sustainability goals. These acts, combined with the IIJA, create a powerful suite of policies encouraging investment in American industrial capabilities.

Diverse Support Mechanisms

Beyond the headline-grabbing acts, various other mechanisms are at play:

- Research & Development (R&D) Tax Credits: Encourage companies to invest in innovation by offsetting the costs of developing new products and processes.

- State-Level Incentives: Many states offer their own tax breaks, grants, and infrastructure support to attract manufacturing facilities, creating a competitive environment for investment.

- Defense Production Act Utilization: In strategic areas, the DPA has been used to accelerate domestic production of critical goods, ensuring national security priorities are met.

These financial incentives and policy frameworks are crucial for de-risking investments in domestic manufacturing, making the financial case for reshoring and technological upgrades more compelling. They demonstrate a clear governmental commitment to fostering a vibrant manufacturing ecosystem, encouraging long-term planning and capital deployment in advanced production capabilities within the United States.

Challenges and Opportunities for Sustained Growth

While the US manufacturing renaissance is marked by significant momentum and strategic investments, it is not without its challenges. Sustaining this growth and ensuring its long-term viability requires a clear-eyed assessment of potential hurdles and a proactive approach to turning them into opportunities. The scale of the transformation, the speed of technological change, and the persistent global competitive landscape present complex issues that demand continuous adaptation and innovation.

One of the foremost challenges remains the aforementioned workforce development. Even with concerted efforts, the gap between the skills available and the skills required by advanced manufacturing technologies can impede progress. Attracting and retaining talent, particularly in niche high-tech areas, is a constant battle. Furthermore, the sheer capital investment required for state-of-the-art factories means that companies need stable, long-term policy predictability to commit fully. Regulatory environments and the cost of doing business in the US, compared to other nations, also factor into investment decisions.

Navigating the Path Forward

Addressing these challenges requires a multifaceted strategy:

- Continuous Workforce Training: Beyond initial programs, there’s a need for ongoing reskilling and upskilling initiatives to keep pace with evolving technologies. Companies must invest in their employees through lifelong learning.

- Attracting Foreign Direct Investment (FDI): While reshoring is important, attracting global leaders in advanced manufacturing further cements the US as a hub for innovation and production. This requires a stable, attractive business environment.

- Balancing Automation and Job Creation: Ensuring that technological adoption leads to higher-value jobs and general economic uplift, rather than significant job displacement, is a critical socio-economic consideration.

Despite these challenges, the opportunities for sustained growth are immense. The potential for the US to lead in critical and emerging technologies like advanced semiconductors, biotechnologies, and sustainable energy solutions remains strong. By strategically leveraging its natural resources, innovative spirit, and robust policy support, the US can solidify its position as a global manufacturing powerhouse, ensuring long-term prosperity and technological leadership in a rapidly changing world.

| Key Point | Brief Description |

|---|---|

| 🏗️ Infrastructure Boost | The $1T bill provides crucial funds for broadband, energy grid, and transport, foundational for modern manufacturing. |

| ⚙️ Tech Upgrades | Focus on Industry 4.0 (AI, IoT, robotics) for enhanced productivity and quality in smart factories. |

| 🔗 Supply Chain Resilience | Incentives catalyze reshoring and nearshoring to mitigate global disruptions and ensure domestic supply. |

| 🧑🎓 Workforce Development | Addressing skills gaps through education, apprenticeships, and training for advanced manufacturing roles. |

Frequently Asked Questions about US Manufacturing Renaissance

▼

The bill allocates funds to critical areas such as broadband internet, modernizing the electrical grid, and upgrading transportation networks (roads, bridges, ports). These improvements provide the foundational infrastructure necessary for advanced manufacturing operations, enabling faster data transfer, reliable power supply, and efficient movement of goods, thereby reducing operational costs and increasing competitiveness.

▼

The core technological upgrades involve widespread adoption of Industry 4.0 technologies. This includes robotics and automation for increased efficiency, Artificial Intelligence (AI) for predictive maintenance and optimization, and the Internet of Things (IoT) for real-time data collection and analysis. These technologies create “smart factories” that are more agile, productive, and responsive to market changes.

▼

Addressing the skills gap involves comprehensive workforce development programs. These include fostering apprenticeships and on-the-job training, establishing stronger partnerships between community colleges and manufacturers to tailor curricula, and promoting STEM education from an early age. The goal is to equip the workforce with the advanced technical and digital skills required for modern manufacturing roles.

▼

“Reshoring” refers to the process of bringing manufacturing operations back to the United States from offshore locations. This trend is driven by a desire for greater supply chain resilience, reduced lead times, improved quality control, and enhanced national security. The infrastructure bill and other policies make domestic production more competitive, accelerating this vital movement for strategically important goods.

▼

Complementary policies include the CHIPS and Science Act, which heavily invests in domestic semiconductor manufacturing, and the Inflation Reduction Act, offering tax credits for clean energy and EV production. Additionally, various R&D tax credits and state-level incentives attract manufacturing investments, collectively creating a robust policy environment encouraging long-term growth and innovation in the sector.

A Resilient and Innovative Future

The convergence of the $1 trillion Infrastructure Investment and Jobs Act with a strategic focus on technological upgrades is indeed fueling a significant US manufacturing renaissance. This is not merely an economic rebound but a fundamental reimagining of American industrial capabilities, driven by a commitment to resilience, innovation, and long-term competitiveness. While challenges persist, particularly in workforce development and securing sustained investment, the groundwork has been laid for a future where US manufacturing is not only robust but also leads the world in advanced production methodologies.