Newest Innovations in US-Based Robotics for Automation: A Deep Dive

The newest innovations in US-based robotics for automation are revolutionizing industries through advanced AI integration, enhanced human-robot collaboration, innovative mobile manipulation, and the development of more adaptable and sustainable robotic systems, fundamentally redefining efficiency and workforce interaction across various sectors.

The landscape of robotics is undergoing a profound transformation, moving beyond the traditional factory floor into virtually every facet of our daily lives. So, what are the newest innovations in US-based robotics for automation impacting industries and society at large? This deep dive explores the cutting-edge advancements originating from the United States, showcasing a blend of pioneering research and practical application that promises to redefine the future of work and interaction.

The Rise of Collaborative Robotics (Cobots)

Collaborative robots, or cobots, represent a significant paradigm shift in automation, moving away from isolated, cage-bound machines to systems designed to work alongside humans. This evolution is driven by the need for more flexible manufacturing and service environments where adaptability is key. US companies are at the forefront of developing cobots that are not only safer but also intuitively easy to program and integrate into existing workflows, democratizing automation for businesses of all sizes.

Enhanced Safety and Human-Robot Interaction

The core of cobot innovation lies in their inherent safety features, making them suitable for shared workspaces. Advanced sensors, force-torque limiters, and sophisticated AI algorithms allow these robots to detect human presence and respond appropriately, preventing accidents and fostering a harmonious working relationship. This level of interaction enhances productivity without compromising human well-being.

- Force-sensing technology: Allows cobots to immediately stop or reduce speed upon detecting unexpected contact.

- Vision systems: Enable cobots to understand their environment and human gestures, leading to more responsive and natural interactions.

- Intuitive programming interfaces: Simplify the teaching of new tasks, often through lead-through programming or graphical user interfaces.

Furthermore, the ability of cobots to adapt to unstructured environments and perform delicate tasks has opened doors in sectors previously untouched by traditional automation, such as intricate assembly and delicate handling of biological samples. The goal is to offload repetitive or ergonomically challenging tasks from human workers, allowing them to focus on more complex, creative, and value-added activities. This enhances job quality and overall operational efficiency.

US manufacturers are increasingly designing cobots with modular components, allowing for rapid customization and deployment. This modularity extends the lifespan of the robotic system and allows businesses to reconfigure their automation solutions as market demands evolve, providing a significant competitive advantage. The integration of augmented reality (AR) often assists in cobot setup and training, making the technology even more accessible to non-specialists.

The continuous development in this space promises even more seamless integrations, where cobots will not just be tools, but genuine partners in a diverse range of operational contexts. Their role extends beyond manufacturing into logistics, healthcare, and even retail, demonstrating their versatility and the profound impact they are set to make.

Advances in Mobile Manipulation and Logistics Automation

The convergence of mobile robotics and advanced manipulation capabilities is driving significant innovation in logistics, warehousing, and field operations. US companies are developing autonomous mobile robots (AMRs) equipped with robotic arms that can not only navigate complex environments but also pick, place, and sort items with unprecedented precision and speed. This capability is crucial for optimizing supply chain efficiency and addressing labor shortages.

Sophisticated Navigation and Dexterous Handling

Modern AMRs integrate advanced sensor suites, including LiDAR, cameras, and even ultrasonic sensors, coupled with sophisticated simultaneous localization and mapping (SLAM) algorithms. This allows them to autonomously navigate dynamic environments, avoiding obstacles and optimizing routes in real-time without needing predefined paths or magnetic tapes. Their ability to dynamically adapt makes them incredibly versatile.

- LiDAR and vision fusion: Provides robust 3D environmental mapping for precise navigation and object recognition.

- Reinforcement learning for manipulation: Enables robots to learn complex grasping strategies through trial and error, improving dexterity.

- Fleet management software: Orchestrates the movements of multiple AMRs, preventing collisions and optimizing task allocation in large-scale operations.

Beyond navigation, the robotic arms integrated onto these mobile platforms are becoming increasingly dexterous. Equipped with multi-fingered grippers, suction cups, or specialized end-effectors, they can handle a vast array of objects, from small, delicate components to bulky, irregularly shaped packages. This dexterity, combined with AI-powered vision systems, allows for accurate item identification and precise placement, reducing errors and damages. The autonomy of these systems reduces the need for human intervention in repetitive and often strenuous tasks.

The impact of this technology extends beyond the walls of warehouses. Mobile manipulation robots are being deployed in outdoor settings for inspections, construction, and even agriculture, where they can perform tasks like precision harvesting or equipment maintenance. Their rugged designs and advanced power management systems ensure operability in varied conditions, making them indispensable for operations looking to gain an edge in efficiency and safety. The continuous improvement in battery technology and fast charging further enhances their operational uptime, making their deployment even more practical.

The fusion of mobility and manipulation is not just about moving goods; it’s about transforming the entire operational flow. By automating the end-to-end process of picking, packing, and transporting, these robots enable businesses to scale rapidly, respond to sudden surges in demand, and maintain competitive pricing in global markets. The logistical challenges of e-commerce are particularly well-suited to these robotic solutions.

AI and Machine Learning Driving Robotic Intelligence

The true intelligence of modern robotics stems from the pervasive integration of Artificial Intelligence (AI) and Machine Learning (ML). These technologies enable robots to perceive, reason, learn, and adapt in ways previously unimaginable, moving them from programmed machines to autonomous problem-solvers. In the US, AI is not merely an add-on but a foundational component in the development of next-generation robotic systems.

Deep Learning for Perception and Decision-Making

Deep learning, a subset of machine learning, has revolutionized how robots interpret sensory data. Convolutional Neural Networks (CNNs) allow robots to accurately identify objects, classify them, and even infer their properties from visual inputs. Recurrent Neural Networks (RNNs) enable them to understand sequential data, crucial for natural language processing when interacting with humans. This advanced perception capability is vital for complex tasks in dynamic environments.

- Real-time object recognition: Essential for robotic arms to accurately pick and place items in variable orientations.

- Predictive maintenance: AI algorithms analyze sensor data from robots to predict potential failures before they occur, minimizing downtime.

- Behavioral adaptation: Robots can learn from human demonstrations or simulated environments, refining their movements and strategies over time.

Beyond perception, AI empowers robots with enhanced decision-making capabilities. Reinforcement Learning (RL), for instance, allows robots to learn optimal strategies through trial and error, much like humans. This is particularly valuable in scenarios where explicitly programming every possible situation is impractical, such as navigating cluttered spaces or performing delicate surgical procedures. The ability to learn and improve autonomously vastly increases the versatility and robustness of robotic systems, reducing the need for constant human supervision.

The synergy between robotics and AI is also fostering advancements in areas like digital twins and simulation. Before deploying a robot in the real world, its behavior can be simulated in a virtual environment, allowing developers to optimize algorithms and identify potential issues without physical prototypes. This iterative learning cycle, accelerated by AI, significantly reduces development time and costs. Furthermore, edge AI processing is becoming prevalent, allowing robots to make real-time decisions without constant cloud connectivity, enhancing responsiveness and security.

As AI models become more sophisticated and data availability increases, robots will exhibit even greater cognitive abilities, moving towards general-purpose intelligence. This trajectory will enable them to tackle highly complex, unstructured problems across diverse industries, from precision agriculture to urban infrastructure maintenance, fundamentally transforming operational paradigms. The ethical considerations of increasingly autonomous systems are also a growing area of research and policy discussion, ensuring responsible development.

Advanced Manufacturing and Industrial Automation

The US is pioneering breakthroughs in industrial automation, pushing the boundaries of what robots can achieve in manufacturing environments. These innovations go beyond mere task execution to embrace concepts like self-optimization, rapid reconfigurability, and increased energy efficiency. The emphasis is on creating smart factories that can react dynamically to market changes and produce highly customized products with mass-production efficiency.

Flexible Manufacturing Systems and Additive Robotics

Traditional manufacturing lines are rigid, designed for mass production of identical items. New robotic systems are built for flexibility, capable of switching between different product variants with minimal downtime. This is achieved through modular robot cells, easily programmable robots, and advanced software that integrates design, production, and quality control. This flexibility is crucial for industries requiring high customization.

- Modular robot workcells: Allow for rapid reconfiguration to accommodate different product designs or production volumes.

- Vision-guided assembly: Robots use cameras to precisely locate components, even if they are not perfectly presented, adapting to variations.

- Real-time process optimization: Sensors and AI monitor production parameters, adjusting robot movements to maintain quality and efficiency.

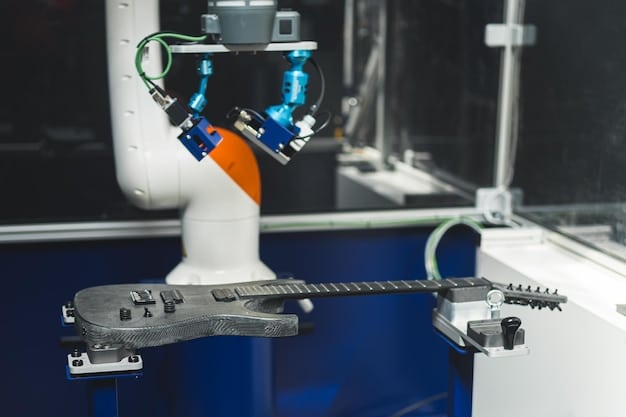

Additive manufacturing, or 3D printing, combined with robotics, is another revolutionary area. Robotic arms equipped with specialized extruders or laser heads can print large-scale structures, complex geometries, or even entire buildings. This “additive robotics” offers unprecedented design freedom, reduces material waste, and allows for local, on-demand manufacturing. It’s particularly impactful in aerospace, defense, and construction, where custom parts and rapid prototyping are critical.

Furthermore, the focus is shifting towards more energy-efficient robotic systems. Innovations in lightweight materials, advanced motor controls, and regenerative braking systems are reducing the power consumption of industrial robots, contributing to more sustainable manufacturing practices. The integration of predictive maintenance, driven by AI, also ensures that these complex machines operate at peak efficiency for longer periods, reducing repair costs and environmental impact. The concept of “lights-out manufacturing,” where factories operate autonomously without human presence during certain shifts, is becoming a tangible reality due to these advancements.

The broader impact of these industrial innovations is a shift towards Industry 4.0 and beyond, where robots are not just performing tasks but are integral components of a connected, intelligent manufacturing ecosystem. This ecosystem allows for greater data flow, better decision-making, and unprecedented levels of automation and customization. The competitive edge provided by such advanced systems is increasingly vital in a globalized economy that demands both efficiency and adaptability.

Robotics in Healthcare and Life Sciences

The US is a global leader in applying robotics to healthcare and life sciences, transforming patient care, drug discovery, and medical procedures. These innovations are enhancing precision, safety, and accessibility in a sector where accuracy is paramount, moving beyond traditional laboratory automation to direct patient interaction and surgical assistance.

Surgical Robots and Diagnostic Automation

Surgical robotics has arguably seen some of the most impactful breakthroughs. Systems like the da Vinci Surgical System, developed by US-based Intuitive Surgical, allow surgeons to perform complex procedures with enhanced precision, dexterity, and visualization through minimally invasive approaches. This reduces patient recovery times, lowers infection risks, and often leads to better patient outcomes. Newer systems are continually being developed to target specific surgical specialties, such as orthopedics or neurosurgery, with greater customization.

- Minimally invasive surgery: Reduces trauma to the patient, leading to faster healing and shorter hospital stays.

- Enhanced dexterity and tremor filtration: Robots can perform movements beyond human capabilities, removing natural hand tremors for extreme precision.

- Improved visualization: High-definition 3D cameras provide magnified views inside the body, offering surgeons unparalleled clarity.

In life sciences, robotics is automating repetitive and high-throughput tasks in laboratories, from pipetting and sample preparation to DNA sequencing and drug screening. This accelerates research and development, allowing scientists to process vast amounts of data and conduct experiments on scales previously unimaginable. Such automation is crucial for rapid vaccine development, personalized medicine, and understanding complex biological processes. The precision capabilities of these robots minimize human error and contamination, ensuring data integrity.

Furthermore, robotics is playing a growing role in patient rehabilitation and assistance. Exoskeletons help patients with mobility impairments regain movement, while companion robots provide social support and monitor vital signs. Robotic pharmacies automate medication dispensing, reducing errors and improving efficiency. The development of smaller, more agile robots for endoscopy and targeted drug delivery is also on the horizon, promising even less invasive diagnostic and therapeutic interventions. Telepresence robots are also enabling remote consultations and monitoring, extending healthcare access to underserved areas.

The future of robotics in healthcare will likely involve even greater autonomy, personalization, and integration with AI-driven diagnostics. Robots will move from assisting human clinicians to performing certain procedures autonomously under supervision, revolutionizing surgical training and access to specialized care. Predictive analytics powered by AI will also inform robotic interventions, making healthcare more proactive and preventative, ultimately enhancing human well-being on a grand scale.

Robotics in Agriculture and Environmental Applications

The US is investing heavily in robotics for agriculture and environmental stewardship, addressing critical challenges such as labor shortages, resource scarcity, and climate change. These innovations aim to make farming more sustainable, efficient, and data-driven, while also enhancing monitoring and preservation efforts in natural environments.

Precision Agriculture and Autonomous Harvesting

Agricultural robots, often referred to as “agribots,” are transforming traditional farming practices into precision agriculture. These autonomous vehicles can plant, monitor, fertilize, and harvest crops with extreme accuracy, reducing waste of water, fertilizer, and pesticides. This level of precision minimizes environmental impact while maximizing yield, which is essential for global food security. The utilization of GPS and advanced mapping technologies allows agribots to operate with centimeter-level accuracy, ensuring optimal resource allocation.

- Weed detection and removal: Robots use vision systems to identify weeds and remove them mechanically or with targeted micro-doses of herbicides, reducing chemical reliance.

- Individual plant monitoring: Sensors track the health and growth of each plant, providing data for personalized care and early disease detection.

- Autonomous harvesting: Robots can identify ripe fruits and vegetables and pick them gently, reducing labor costs and crop damage.

In environmental applications, robots are being deployed for monitoring ecosystems, detecting pollution, and assisting in disaster response. Autonomous underwater vehicles (AUVs) collect data on ocean health, while aerial drones equipped with multispectral cameras track deforestation and wildlife populations. Ground robots can explore hazardous environments, such as contaminated sites or areas affected by natural disasters, providing critical information for cleanup and rescue efforts without risking human lives. Their ability to collect consistent, high-resolution data over vast areas makes them invaluable tools for environmental science and conservation.

The development of bio-inspired robots, which mimic the movements and behaviors of living organisms, is also gaining traction for environmental applications. For example, snake-like robots can navigate rough terrain or tight spaces for infrastructure inspection or search and rescue. Soft robotics, using flexible materials, is enabling robots to interact with delicate organisms or unstable environments with minimal disturbance. These innovations are pushing the boundaries of where and how robots can effectively operate, making them adaptable to unpredictable natural conditions.

The long-term impact of robotics in these sectors includes a more resilient food supply chain, more effective environmental protection, and a safer approach to hazardous tasks. As sensor technology improves and energy efficiency increases, these robots will become even more pervasive, contributing significantly to global sustainability goals. Their data-gathering capabilities are also critical for informing policy and scientific research related to climate change and resource management.

Education and Workforce Training for the Robotic Age

As robotics becomes increasingly pervasive, the US is also focusing on developing robust educational pathways and workforce training programs to prepare the next generation for the robotic age. This involves not only training engineers and researchers but also equipping technicians, skilled tradespeople, and even general workers with the skills necessary to interact with, program, and maintain advanced robotic systems.

STEM Education and Reskilling Initiatives

Early exposure to robotics and automation concepts in STEM (Science, Technology, Engineering, and Mathematics) education is crucial. K-12 programs are incorporating robotics kits, coding challenges, and project-based learning to foster computational thinking and problem-solving skills from a young age. Universities are expanding their robotics curricula, offering specialized degrees and research opportunities in areas like AI for robotics, human-robot interaction, and autonomous systems. This foundational knowledge is essential for innovation.

- Robotics competitions: Encourage teamwork and practical application of robotic principles among students.

- University-industry partnerships: Facilitate internships and research collaborations, ensuring academic training is aligned with industry needs.

- Online courses and certifications: Provide accessible pathways for individuals to gain new skills in robotics programming and operation.

For the existing workforce, reskilling and upskilling initiatives are vital to bridge the gap between traditional roles and those required in automated environments. Community colleges and vocational schools are offering programs focused on robotic operation, maintenance, and basic programming. These programs often include hands-on training with industrial robots and cobots, ensuring graduates are job-ready. The emphasis is on developing a hybrid workforce where human workers supervise, troubleshoot, and collaborate with robots, enhancing overall productivity.

Government initiatives and private sector investments are supporting these training efforts, recognizing that a skilled workforce is critical for maintaining a competitive edge in advanced manufacturing and technology. Apprenticeships and on-the-job training programs are also becoming more common, providing practical experience alongside theoretical knowledge. The focus is not just on technical skills but also on critical thinking, adaptability, and complex problem-solving – attributes that remain uniquely human even in highly automated workplaces.

The long-term vision is a workforce that views robots not as replacements, but as tools that augment human capabilities, freeing individuals from repetitive or dangerous tasks and allowing them to focus on higher-value activities. This educational shift ensures that the benefits of robotic innovation are widely accessible, driving economic growth and societal progress. The proactive approach to workforce preparation is a key differentiator for the US in the global robotics landscape, ensuring sustained innovation and adoption of these transformative technologies for decades to come.

| Key Innovation | Brief Description |

|---|---|

| 🤝 Collaborative Robots | Designed for safe human-robot interaction, increasing flexibility and efficiency in shared workspaces. |

| 🚚 Mobile Manipulation | Autonomous robots with arms for versatile navigation and precise object handling in logistics and field operations. |

| 🧠 AI & Machine Learning | Empowering robots with advanced perception, decision-making, and adaptive learning capabilities for complex tasks. |

| 👨⚕️ Healthcare Robotics | Enhancing surgical precision, automating lab procedures, and assisting in patient care and rehabilitation. |

Frequently Asked Questions (FAQ)

▼

Cobots, or collaborative robots, are designed to work safely alongside humans in shared spaces without physical barriers. Unlike traditional industrial robots, which are typically caged and operate in isolation due to safety concerns, cobots feature advanced sensors and force-limiting technologies that allow them to detect and react to human presence, preventing collisions and enabling direct human-robot cooperation on tasks.

▼

AI is crucial for modern robotics, enabling advanced perception, decision-making, and adaptability. Through machine learning, robots can interpret complex sensory data, learn from experience, and even predict outcomes, allowing them to perform intricate tasks in dynamic environments. AI empowers robots to self-optimize, learn new behaviors, and interact more intelligently with their surroundings, moving beyond pre-programmed actions.

▼

Mobile manipulation robots combine autonomous navigation with robotic arm capabilities, revolutionizing logistics. They can move freely within warehouses or even outdoor environments while simultaneously picking, sorting, and placing items. This significantly enhances efficiency, reduces manual labor, minimizes errors, and allows for flexible scaling of operations, critical for modern supply chains and e-commerce fulfillment.

▼

Robotics are transforming US healthcare by improving surgical precision, automating laboratory procedures, and assisting in patient care. Surgical robots enable minimally invasive operations with enhanced dexterity. Lab automation accelerates drug discovery and diagnostics. Additionally, robots aid in rehabilitation, deliver medications, and provide support to patients, ultimately leading to safer, more efficient, and more accessible healthcare services and outcomes.

▼

Key challenges in deploying new robotic innovations include high initial investment costs, the need for skilled personnel to operate and maintain them, and integration complexities with existing infrastructure. Ethical considerations regarding job displacement and data privacy are also significant. Ensuring robots can adapt to unstructured environments and maintaining robust cybersecurity measures are ongoing areas of research and development for seamless integration.

Conclusion

The US-based robotics sector is a hotbed of innovation, continually redefining the boundaries of automation. From the seamless collaboration of cobots on factory floors to the life-saving precision of surgical robots and the agricultural efficiencies brought by agribots, these advancements underscore a national commitment to technological leadership. The integration of advanced AI, coupled with a proactive approach to workforce training, ensures that these innovations are not just theoretical but deliver tangible, transformative benefits across diverse industries. As these technologies mature, their impact will undoubtedly deepen, creating more efficient, safer, and ultimately more productive futures for businesses and individuals alike.