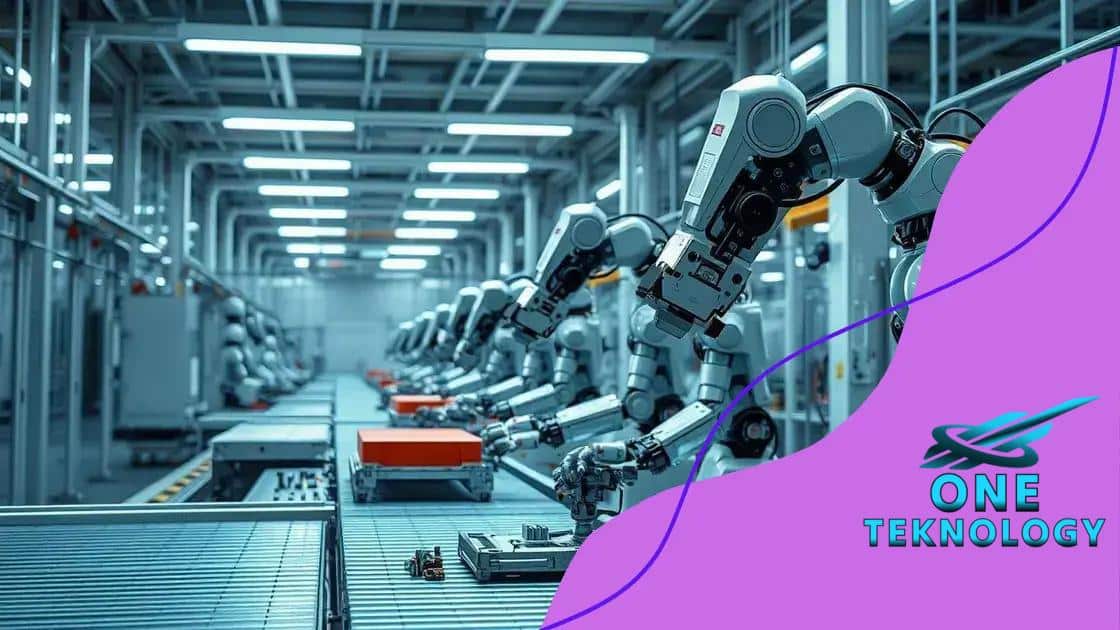

The role of robotics in modern manufacturing processes

The role of robotics in modern manufacturing processes enhances efficiency, productivity, and safety through automation, advanced AI integration, and collaboration with human workers, shaping the future of the industry.

The role of robotics in modern manufacturing processes has been a game changer for industries worldwide. Ever thought about how these technologies might influence your world? Let’s dive in!

Understanding the evolution of robotics in manufacturing

The evolution of robotics in manufacturing is fascinating and has greatly influenced how industries operate today. Over the years, machines have become more capable, reliable, and smarter, transforming factories into advanced automated environments.

Early Developments in Robotics

Initially, robotics in manufacturing started with simple machines like conveyors and rudimentary robotic arms. These early technologies helped move products but did not have the flexibility or intelligence that modern robots possess. As technology advanced, so did the capabilities of these machines.

Generations of Robotics

There are several generations of robotics that have marked significant milestones in manufacturing:

- First Generation: Basic automation, involving mechanical devices.

- Second Generation: Introduction of programmable robots, enhancing flexibility.

- Third Generation: Intelligent robots with AI functionalities for decision-making.

The continuous improvement in robotics leads to increased efficiency and productivity in manufacturing processes. Modern robots can perform complex tasks with high precision and minimal human intervention. They are often equipped with sensors and artificial intelligence, enabling them to adapt to changing environments and tasks. This flexibility is essential for meeting consumer demands in today’s fast-paced market.

The Role of AI in Robotics

The integration of artificial intelligence has pushed the capabilities of robotics to new heights. Robots can now learn from their experiences and make real-time decisions without human assistance. This technology is revolutionizing industries by allowing for the creation of automated processes that are efficient and responsive to customer needs.

Furthermore, advanced robotics enhances safety and reduces operational costs while increasing output quality. The shift towards smart manufacturing can be observed, with industries embracing automation to improve not only production rates but also working conditions for employees, thanks to safer environments.

Overall, the understanding of the evolution of robotics in manufacturing gives insight into how far we have come and the exciting possibilities ahead. With ongoing research and development, the future is bright for robotics in manufacturing, as these technologies continue to advance and reshape how we think about production.

Key benefits of robotics in modern factories

The key benefits of robotics in modern factories are numerous and impactful. These innovations have changed the landscape of manufacturing, providing efficiency and quality like never before.

Increased Productivity

One of the primary advantages of utilizing robotics is the significant boost in productivity. Robots can work faster than humans, completing tasks in a fraction of the time. This speed allows factories to increase output and meet customer demand more effectively.

Enhanced Precision and Quality

Robots are designed to perform tasks with incredible accuracy. This precision minimizes errors and improves the quality of the products being manufactured. When quality control is enhanced, customer satisfaction rises, leading to greater brand loyalty.

- Consistent quality: Robots do not tire or become fatigued, ensuring that each product meets the same high standards.

- Reduced waste: Accurate measurements and operations decrease the likelihood of waste in materials during production.

- Improved safety: Fewer errors in execution can lead to a safer working environment.

Furthermore, the implementation of robotics in factories often leads to lower operational costs in the long run. Although the initial investment may be substantial, the savings gained from reduced labor costs and fewer mistakes quickly outweigh expenses.

Robots can also contribute to a safer work environment. By taking over dangerous tasks, they help decrease workplace accidents. This is especially important in industries where workers face hazardous conditions, allowing them to focus on more complex and less dangerous roles.Automation enables workers to shift from repetitive tasks to problem-solving and management positions, improving job satisfaction and skill development.

Additionally, robotics enhances flexibility in manufacturing processes. These machines can be reprogrammed and outfitted with different tools to handle various tasks, allowing factories to adapt to changing demands quickly.

How robotics improves efficiency and productivity

Robotics plays a crucial role in enhancing efficiency and productivity in various industries. By automating repetitive tasks, robots free up human workers to focus on more complex activities that require creativity and problem-solving.

Streamlined Operations

One major way that robotics improves industrial efficiency is through streamlined operations. Robots can perform tasks at a consistent speed and without breaks, which reduces production time. This efficiency leads to higher output and faster turnaround times for products.

Reduction of Human Errors

Another benefit is the significant reduction of human errors. When robots are programmed correctly, they execute tasks with nearly flawless accuracy. This reliability ensures that the quality of products remains high.

- Consistent performance: Robots maintain the same speed and quality of work throughout their operation.

- Less rework: Fewer mistakes lead to lower costs related to corrective measures.

- Data-driven improvements: Many robots are equipped with sensors that collect data, allowing for analysis to improve processes further.

Moreover, robots can operate in environments that might be unsafe for humans, thus maximizing the use of labor where it’s needed most. This ability to handle dangerous or difficult tasks allows companies to allocate human resources to areas where creative thinking and strategic decision-making are essential.

With the addition of robotic technologies, companies often see an increase in production rates. Enhanced productivity means that businesses can meet consumer demand more quickly and efficiently, leading to increased sales and market competitiveness.

Additionally, robots can work around the clock without fatigue, which significantly increases operational hours. This capability allows businesses to operate more effectively and maximize their output, helping them keep pace in today’s fast-moving market.

Real-world applications of robotics in manufacturing

Real-world applications of robotics in manufacturing demonstrate the power of automation in diverse fields. From automotive assembly lines to electronics production, robots have transformed how goods are made.

Automotive Industry

One of the most notable sectors using robotics is the automotive industry. Robots are essential in assembling vehicles, performing tasks such as welding, painting, and installing parts. Their ability to work quickly and consistently helps manufacturers maintain high production rates.

Electronics Manufacturing

In electronics, robots handle delicate components with precision. They assemble circuit boards, place tiny components, and test products for quality assurance. This attention to detail minimizes errors and ensures that devices function correctly.

- Quality control: Robots can inspect products using vision systems, identifying defects more effectively than humans.

- High-speed assembly: Robotics dramatically reduce the time needed to produce complex electronics.

- Adaptability: They can quickly switch tasks based on production needs.

Robots are also making headway in the food and beverage industry. They automate repetitive tasks such as packing, sorting, and even cooking. This helps companies scale production while ensuring food safety standards are met.

In addition, the pharmaceutical sector utilizes robotics for packaging and labelling. Robots work in clean environments to handle medications efficiently, ensuring accuracy and maintaining safety protocols. With the ability to process large volumes of products, robots help meet the demands of healthcare systems.

Furthermore, collaborative robots, or cobots, are emerging as vital assets in manufacturing. Unlike traditional robots, cobots are designed to work alongside human operators. They assist in tasks that require human intuition, making work safer and enhancing overall productivity.

Future trends in robotics for manufacturing industries

The future trends in robotics for manufacturing industries point towards even greater integration of technology into production processes. As innovations continue to emerge, manufacturers are finding new ways to enhance efficiency and reduce costs.

Advanced Automation

One major trend is the move towards advanced automation. Robots are becoming smarter, incorporating artificial intelligence (AI) and machine learning. This allows them to adapt to changing environments and optimize operations without human intervention.

Collaboration Between Humans and Robots

Another significant trend is the rise of collaborative robots, or cobots. These robots are designed to work alongside human workers, enhancing productivity while ensuring safety. Cobots can assist with tasks that are repetitive or physically taxing, enabling human workers to focus on more skilled activities.

- Intuitive Programming: Cobots have user-friendly interfaces that allow employees to train them easily.

- Wider Adoption: Businesses of all sizes are adopting cobots, making automation accessible to small and medium enterprises.

- Enhanced Safety: Cobots are equipped with sensors that prevent accidents in shared workspaces.

Additionally, the future of robotics in manufacturing includes the use of big data and analytics. Robots will not only carry out tasks but will also collect data that can be analyzed to improve production processes. This data can lead to insights that help in predictive maintenance, reducing downtime, and enhancing overall productivity.

Moreover, sustainability is becoming a key focus. Future robotic systems will be designed to be energy efficient and to minimize waste during production. Companies are increasingly aware of their environmental impact and seek solutions that align with eco-friendly practices.

Finally, as technology advances, there will be more integration of robotics with the Internet of Things (IoT). This connection will allow robots to communicate with other machines and systems, creating a more cohesive and efficient manufacturing environment.

FAQ – Frequently Asked Questions about Robotics in Manufacturing

How do robotics improve efficiency in manufacturing?

Robotics enhance efficiency by automating repetitive tasks, allowing for faster production rates and reducing human errors.

What are collaborative robots (cobots)?

Collaborative robots are designed to work alongside human operators, assisting them with tasks while ensuring safety and enhancing productivity.

What role does AI play in modern robotics?

AI enables robots to learn from their experiences and adapt to changing tasks, making them more efficient and capable in various environments.

What future trends can we expect in robotics for manufacturing?

Future trends include increased use of AI, data analytics, collaboration between humans and robots, and a stronger focus on sustainability in robotic systems.